Fatra FF810 Membranes: PVC fixing disc installation

The Fatra mechanically fastened system uses our FF810 reinforced membranes in conjunction with the appropriate fixings, washers, PVC fixing discs and adhesives to secure the membrane to the substrate. This system can be used in a warm or cold roof application and over a range of substrates including profiled metal decking, plywood and concrete.

There are 2 standard roll sizes available:

|

Fatra FF810 Membranes

|

|

Reference

|

Fatra FF810

|

Fatra FF810V

|

|

Roll width

|

1,300mm

|

2,050mm

|

|

Roll length

|

20m

|

20m

|

|

Thickness

|

1.5mm

|

1.5mm

|

|

Area

|

26m2

|

41m2

|

|

Roll weight

|

52kg

|

82kg

|

|

Unit weight

|

2.0 kg/m2

|

2.0 kg/m2

|

|

Rolls per pallet

|

19

|

21

|

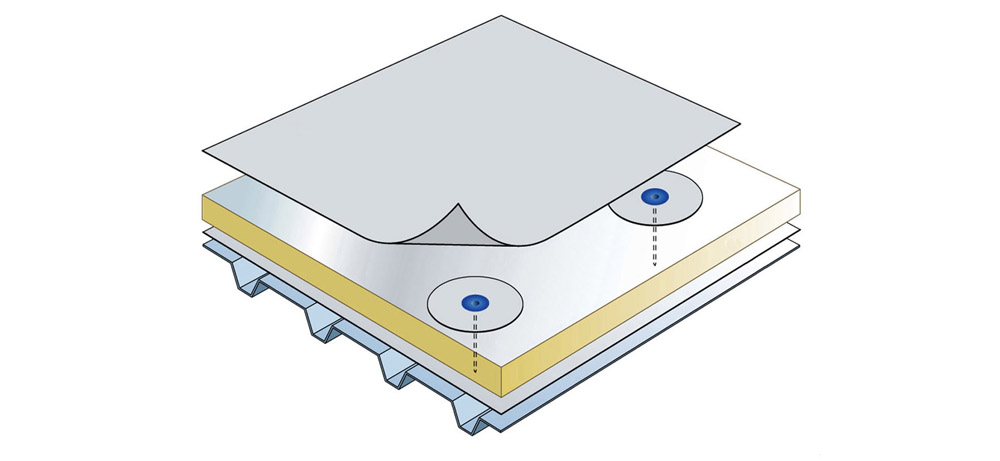

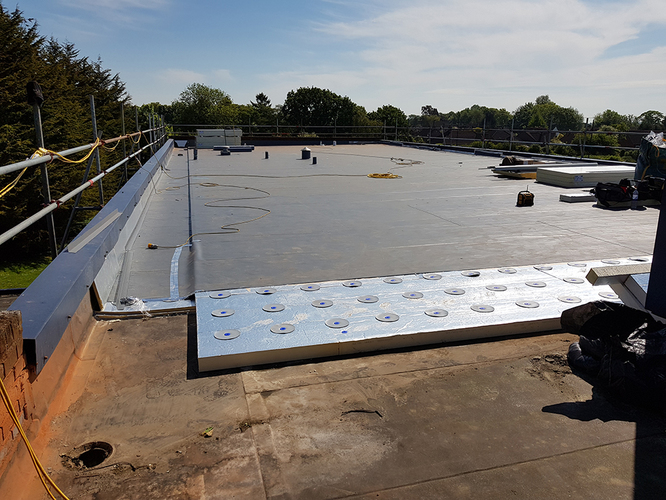

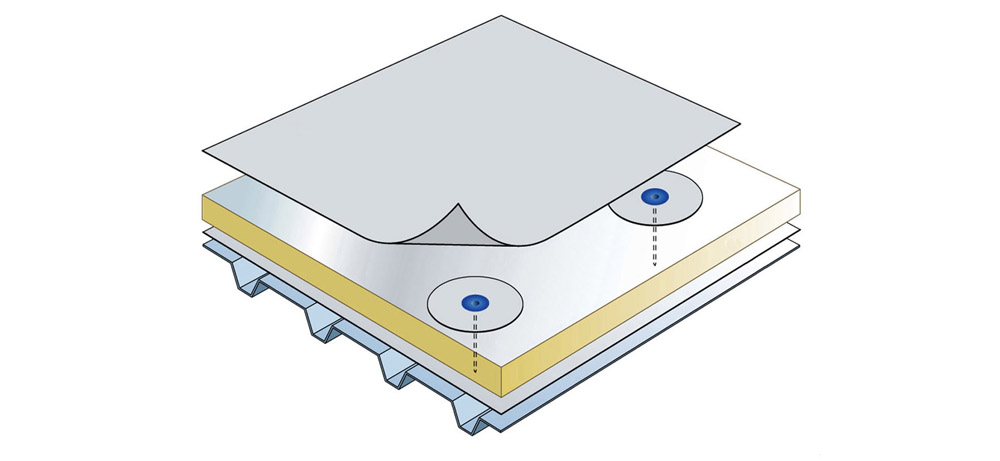

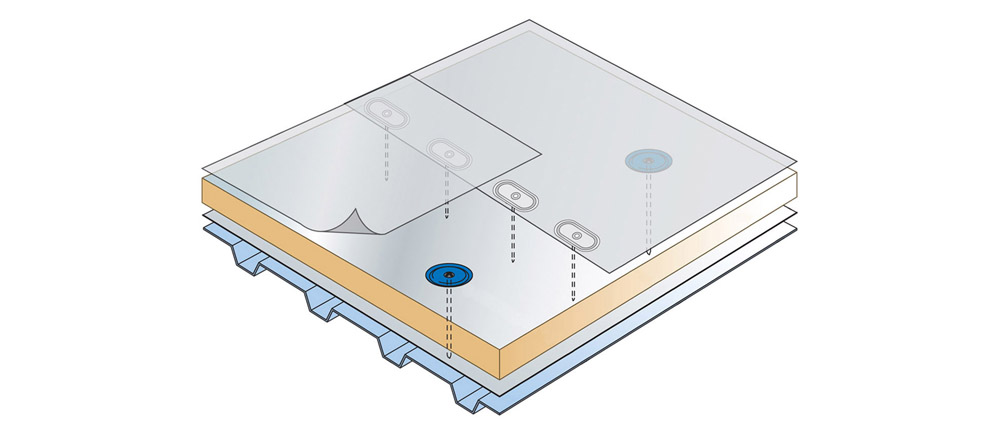

Typical warm roof installation

Lay FF818 polythene VCL loose over the substrate and tape all joints with Fatra FA1 butyl sealant tape, allowing for 100mm side and end laps. Loose lay the insulation board to a staggered bond pattern, following the manufacturer’s installation recommendations.

Set out FF852 PVC fixing discs to the fixing design, provided by the Fatra Technical Department, using the specified Fatrafix fixings (FR-45 tube washers with the appropriate fastener). Across the width of the membrane sheet the discs should be fixed in accordance with the fixing design but not greater than 650mm centres. The row of fixings closest to the roof perimeter should be set out no more than 200mm away from the perimeter.

Using the toothed applicator (supplied), apply FF855 adhesive to the FF852 discs. Carefully line up the FF810 membrane and roll it out over the discs. Pull the membrane tight and then consolidate the bond, either by hand or with a roller / soft broom.

Adjacent rolls of membrane must overlap by a minimum of 50mm. The laps are then hot air welded with a heat gun to create a homogeneous, watertight seal.

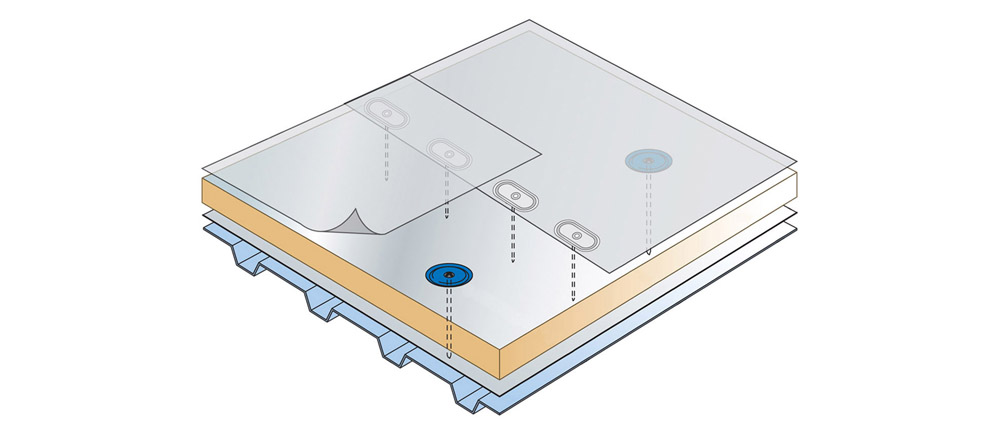

Fatra FF810 Membrane: Side-lap fixed installation

Fatra FF810 reinforced membrane can also be mechanically side-lap fixed as an alternative option to the FF852 PVC fixing disc system. In this build-up, the membrane and insulation are secured independently.

Typical warm roof installation

When side-lap fixing, Fatra FF810 1.3m wide membrane must be used, with each sheet overlapping the adjacent sheet by 120mm. The fixings should be spaced at 150mm centres along the length of the roll and the edge of the washer should be no less than 10mm away from the edge of the membrane.

Insulation boards should be secured independently in a side-lap fixed installation. Use an FR-75 tube washer with the appropriate fastener (FBS-5.8 for steel / plywood, FHD-6.1 for concrete).

When fastening the membrane, use either an FF853O 82mm x 40mm steel plate washer or an FR-45 tube washer with a fastener. If using a tube washer, ensure a suitable tool is used to puncture the membrane: do not snip the edge of the roll.

Once the membrane has been fixed, roll the next section of FF810 membrane over the sheet that has been secured, carefully lining up the membrane to achieve a 120mm overlap. This provides enough space to cover the fixings and to achieve a full hot air weld.

Side-lap fixing should also be used for all vertical upstands greater than 600mm in height.